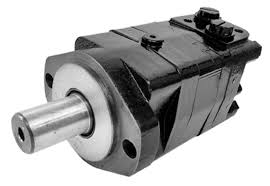

Hydraulic motors are used in any application requiring rotational force, also referred to as torque. A hydraulic engine converts hydrostatic energy into mechanical energy by pressing vanes, gears or pistons mounted on a crankshaft.

Hydraulic motors are utilized for most applications now such as for example winches and crane drives, wheel motors for military vehicles, self-driven cranes, excavators, conveyor and feeder drives, cooling fan drives, mixer and agitator drives, roll mills, drum drives for digesters, trommels and kilns, shredders, drilling rigs, trench

Hydraulic motors are rotary actuators that convert hydraulic, or fluid energy into mechanical power. They work in tandem with a hydraulic pump, which converts mechanical power into liquid, or hydraulic power. … Fixed-displacement motors drive a load at a constant speed while a continuous input flow is provided.

Across all hydraulic applications, EP offers a broad selection of hydraulic motors from the industry leaders in quality and reliability.Engine types and configurations are for sale to application requirements ranging from low-speed high-torque, all the way to high-quickness high-power, and everything in between.

Hydraulic motors are among the many mechanical components that produce your machinery work just how it’s supposed to. Right here, we appear at what hydraulic motors are, and just why they’re important.

What are Hydraulic Motors?

A hydraulic motor converts hydraulic energy into mechanical energy; a rotating shaft. It uses hydraulic pressure and flows to create the required torque and rotation. You may use hydraulic motors for most applications, such as winches, crane drives, self-propelled farming apparatus, excavators, mixer and agitator drives, roll mills, etc.

The power produced by a hydraulic engine depends upon the flow and pressure drop of the motor. The displacement and pressure drop of the motor determines the torque it creates. The power output is thus directly proportional to the rate. The hydraulic motors range from high-speed motors as high as 10,000 rpm to low-quickness hydraulic motors with at the least 0.5 rpm. Low-quickness hydraulic motors can generate large torques at low speeds.

The hydraulic motor should be targeted at hydraulic system requirements; problems such as load, operating pressure, acceleration, serviceability, etc. should be considered. There are various kinds of hydraulic motors, such as hydraulic gear motors (inner and external), piston motors and hydraulic vane motors, to mention a few.

What Does Engine Displacement Mean?

Motor displacement refers to the quantity of fluid necessary to turn the motor output shaft through a single revolution. The most typical units of motor displacement are in.3 or cm3 per revolution. Hydraulic motor displacement may be fixed or adjustable. A fixed-displacement motor provides continuous torque. Controlling the quantity of input flow into the motor varies the rate. A variable-displacement motor provides variable torque and variable quickness. With input circulation and pressure continuous, varying the displacement can vary the torque-swiftness ratio to meet load requirements.

Torque Result and Hydraulic Motors

Torque output is expressed in inch-pounds or foot-pounds or in Newton meters. It really is a function of system pressure and motor displacement. Motor torque ratings usually are given for a specific pressure drop over the motor. Theoretical statistics indicate the torque available at the motor shaft, assuming no mechanical losses.

Breakaway torque is the torque required to get a stationary load turning. More torque is necessary to start lots moving than to keep it moving.

Running torque can refer to a motor’s load or to the motor. When it identifies a load, this implies the torque necessary to keep the load turning. When it refers to the motor, it indicates the actual torque that a motor can develop to keep lots turning. Working torque considers a motor’s inefficiency and is a percentage of its theoretical torque. The working torque of common equipment, vane, and piston motors is usually approximately 90% of theoretical.

WHAT IS A HYDRAULIC MOTOR AND JUST WHY DO YOU NEED IT?

The look of a hydraulic engine and a hydraulic pump are extremely similar. For this reason, some hydraulic pumps with set displacement volumes may also be used as hydraulic motors. A hydraulic motor works the other method round as it converts hydraulic energy into mechanical energy: a rotating shaft. It uses hydraulic pressure and circulation to generate the required torque and rotation. The power made by a hydraulic electric motor is determined by the movement and pressure drop of the electric motor.

THE DESIGN OF HYDRAULIC PUMPS AND MOTORS IS QUITE SIMILAR. SOME PUMPS CAN BE USED AS HYDRAULIC MOTOR!

You may use hydraulic motors for many applications, such as winches, crane drives, self-driven cranes, excavators, mixer and agitator drives, roll mills, etc. The hydraulic motor must be geared to hydraulic system requirements; problems such as load, range of load, velocity, serviceability, etc. should be taken into account. There are various kinds of hydraulic motors, such as for example hydraulic equipment motors, piston motors and hydraulic vane motors.

Flow and pressure equivalent  power of the motor whereas displacement and pressure drop determine torque.

power of the motor whereas displacement and pressure drop determine torque.

The power produced by a hydraulic engine depends upon the flow and pressure drop of the electric motor. The displacement and pressure drop of the motor determines the torque it creates. The power output is thus straight proportional to the rate. The hydraulic motors range between high speed motors as high as 10,000 rpm to low speed hydraulic motors with at the least 0.5 rpm. Low rate hydraulic motors generate large torques at low speeds.

Not sure what type of hydraulic motor you need? do not be concerned. Our experienced team will help you in buying a new unit. In addition, we can assist you to directly source the outdated hydraulic pumps.

Hydraulic motors enjoy a vital role in hydraulic systems and machinery. Deciding on the best motor in the end saves you a lot of money since it prevents potential failures and costly operational disruptions. We’ve the flexibility for the best delivery time as far as possible without disturbing the parts and assure full operation mechanism.

We also provide hydraulic oil motor repair solutions in piston motors with adverbial clauses: vane motors. Our restoration and refurbishment hydraulic motors make almost no difference to a brand new unit. In addition to motor restoration, we also. Repair adverbial clauses: supply hydraulic cylinders, hydraulic essential oil pumps and hydraulic oil power stations.

Our technical sales engineers are happy to go deeper and provide all the technical information about the equipment we provide. In essence, our priority is to determine the perfect example of your system.

We only display a little part of our item supply. Please do not hesitate to get hold of our friendly team for personalized service information adverbial clause: any part of hydraulic oil.